Your Custom Text Here

These knives and projects are no longer available, this is an archive page.

These are the five knives I used to pass my American Bladesmith Society Journeyman Smith test. The knives are submitted to a panel of six judges who critique the overall appearance, fit, and finish of the knives to determine if the quality of the maker's work is up to a standard expected by the ABS.

Kitchen Cutlery

"Bats & Stag" Damascus Bowie

"Bats & Butterflies" Damascus Bowie

"Mirage Fighter"

"Buckeye Burl Bowie"

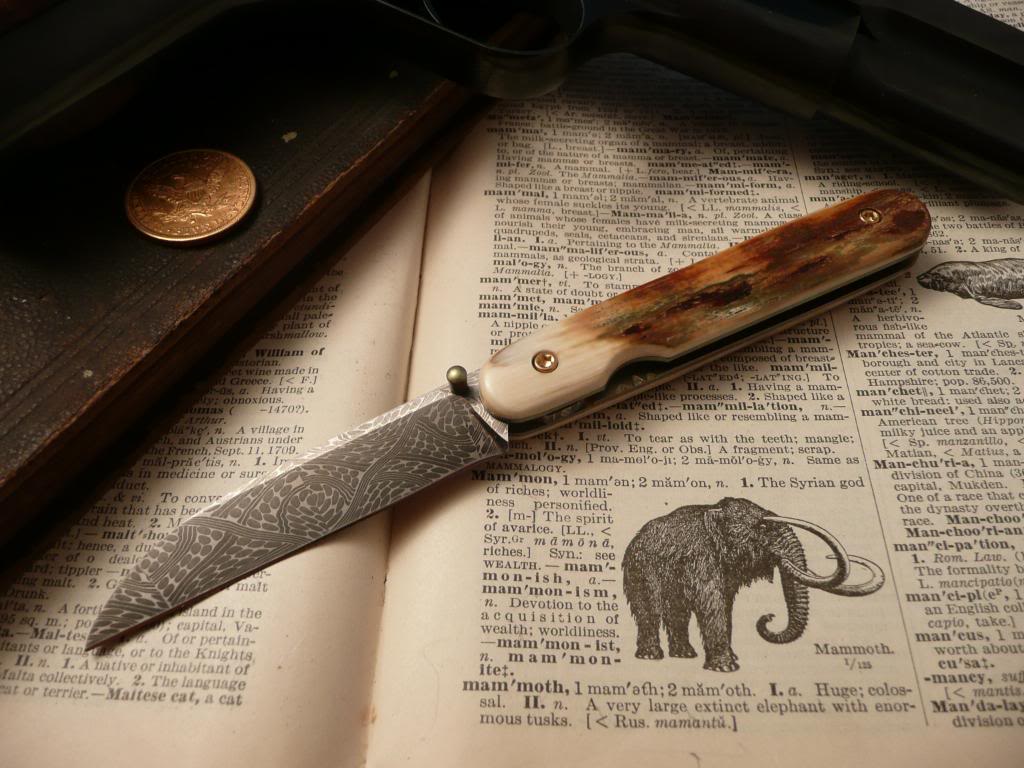

Mosaic Damascus Cigar Knife

This is one of my cigar knives. The blade is "Mind Melt" mosaic damascus with a nitre blue finish. The handles are unbelievable blue and tan mammoth ivory. The liners, back spacer and thumb stud are titanium anodized a matching blue.

Oal open: 5 7/8"

Oal closed: 3 3/8"

Blade: 2 1/2"

PIT - VIPER

The PIT-VIPER is somewhat of a "midtech" design. I have farmed out some of the more laborsome tasks to help reduce costs. The Blade profile has been cut out by waterjet, and the handle scales have been cut out using a 3-axis cnc machine. The rest of the knife is completely built by hand, one at a time. I still do all of my blade grinding, heat treat, cryo, and final fit and finish.

Every PIT-VIPER comes with my personal guarantee against defect, FREE lifetime sharpening, and a certificate of Authenticity and Rockwell Hardness Test.

Specs:

Steel: CPM154

Thickness: .250"

OAL: 14 3/4"

Blade: 8 1/2"

Handles: Canvas Micarta

Handle Colors: Green or Black

Sheath: Kydex with Tek-Lok system

Sheath Option: Handmade wet-formed Leather.

The first run of ten were marked, "ONE of TEN"!! There will be none numbered after that.

Due to a large number of requests for a more "TACTICAL" version of my VIPER, I have designed the "PIT-VIPER" to fill those extreme needs!

Mosaic Damascus Dag that I finished for the Blade Show.

OAL is 13 1/4" with a 8" blade. The guard and butt-cap are also Mosaic Damascus. The handle is African Blackwood and the spacers are nickle silver.

3-FINGER HUNTER

Ribbon Pattern Mosaic Damascus

Sculptured Nickel Silver Bolsters engraved by Darrin Reeves

Cream & Green Mammoth Ivory Scales

"Starburst" Mosaic Damascus Hunter

Steel: Mosaic Damascus from 1084/15n20

OAL: 11"

Blade: 5 1/4"

Handle: Fossil Walrus Ivory & Desert Ironwood

H/T: Differential edge quench

Fittings: Nickel Silver & Copper

note: This was the first Damascus knife with my new J.S. stamped on it!!

My Medium Bull Nosed Skinners are a great skinning tool. They are small and compact measuring just 6" OAL. They have a 2 3/4" deep bellied blade that is suitable for skinning even the largest of big game animals.

Sportsman Knives

My line of Sportsman Series Knives were made for The Sportsman & Ski Haus in Kalispell, Montana for a limited time.

I forged this knife from 1084 tool steel.It has a clay back differential heat treat causing a striking hamon. The 5" clip-point blade has a full flat grind with a convex edge.. The handle is Sambar stag and ivory with copper spacers and a 416 guard.

Danaher Hunter

Forged 1084 tool steel (edge quenched)

Sculptured 416 Stainless Bolsters

Stabilized Afzelia Lay Scales

OAL- 10"

Blade 4.5"

I forged this knife from 1095 tool steel.It has a differential heat treat causing a striking hamon. The 5" clip-point blade has a full flat grind with a convex edge, hand rubbed to 1200 grit. The guard and buttcap are 416 stainless with copper spacers and the handle is Sambar stag. This knife won Best Hand Forge Knife at the 2005 MKA Knife Show!!

S.K Knives Dog Tag

A limited run of Steel Flame copper stamped dog tags were created for MYCKS in November of 2016

For a small side project a couple dozen valve stem caps were produced for dirt bikes.

An Appropriate Use of Shrapnel

I got an e-mail a while back from a customer of mine. He was

inquiring about the possibility of making a knife similar to the one he

had just purchased from me. He said a friend of his had been admiring

his knife and wanted to know if I could make him one too.. So, far this

conversation was sounding like a no brainer....

Then he want on to ask if there was any way that I could use the

shrapnal that the doctors took out of his friend's body, in the Damascus.

Apparantly his friend had a not so friendly mortar explode and tear his

lower body and legs to pieces while deployed at everyones favorite war...

I told him that I had never attempted to use something like that in

Damascus before and had no idea if I could even make it weld to the rest

of the billet. He assured me that he understood and if it didn't work

out then there was no problems.. The shrapnel was just sitting in a jar

in a closet anyway..

A couple weeks later I received a package with a jar containing a piece of

shrapnel just a bit smaller than a golf ball.

I tried to figure out what I was going to do with it. Knowing full well

that this was a one time shot.. If I screwed it up, there were no 2nd

chances to make it work..

I decided to put the piece into the forge and try to forge it into a

small square bar. The whole time it was in there I just prayed that it

didn't burn up or melt, since I had no idea what this stuff was made out

of.. I was assuming it was something like old smashed up Fords or

Chevys or something...

God was kind enough to let that part sorta work out. But when I was

done, there wasn't really that much to work with. I mean it was a huge

chunk of steel to have thrust into the human body.. But, not much in the

whole scheme of a Damascus billet.

I wanted the shrapnel to be readily recognizable within the knife

blade. I wanted to be able to point to it and say, "this is the shrapnel

from your legs, right here!!!". So, I put the bar of shrapnel into a

can and encapsulated it in powdered tool steel and nickel. I then forged

that into a bigger bar that would work into the overall scheme of the

Damascus pattern I was trying to develop.

I wanted the Damascus pattern to look like an exploding piece of steel,

with the shrapnel as the center piece. So, I built a bar of W's and re

squared the shrapnel into the corner of the bar. I then 4 wayed the bar

and re welded it all back together.

I accordion cut the bar and ended up with just enough steel to build the

knife blade and bolsters.

I finished off the handles with camo green G-10, titanium liners and a

Damascus back spacer.

I did a lot of praying while I built this knife.. I prayed that I

wouldn't screw it up.. I prayed for the man that I was building it

for... I prayed for all the fine men and women who have had their lives

so drastically changed keeping me and my family safe...

I have to say that finishing this knife was probably one of the proudest

moments of my 10 years of knife making.. And, that I feel so honored to

be able to give this knife to such a fine man.

Simple words of gratitude can never express the thanks that we owe to so

many unselfish people who assure that we can wake up every day living

in freedom!!!